Air Over Hydraulic with ABS

Air-over-hydraulic brake line kit with ABS trailer brake kitting systems.

TH Series Air Over Hydraulic Trailer Kits – with ABS

A typical Air-over-Hydraulic (A/H) Anti-Lock Brake System (ABS brakes) consists of wheel speed sensors, an ABS relay valve, an integral Electronic Control Unit (ECU) and an A/H booster. The ECU monitors wheel speeds through the use of two wheel speed sensors mounted on the hubs of the trailer axle. An exciter, also referred to as a tone ring, is a required component of the wheel speed sensing system and is usually included on the axle as received from the axle manufacturer.

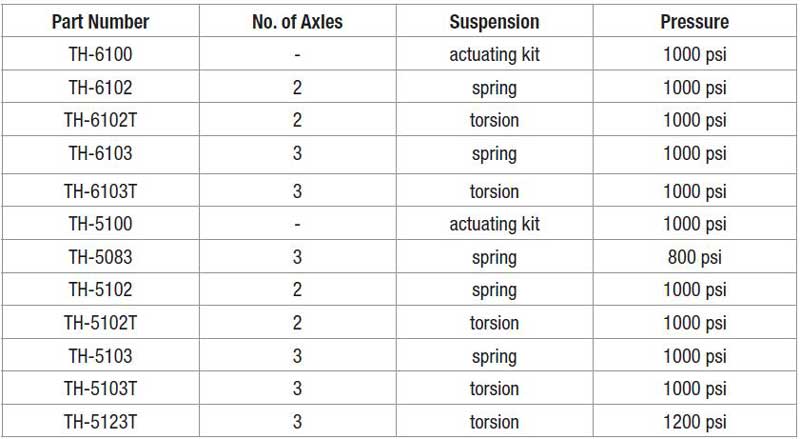

The TH series of Air-over-Hydraulic ABS trailer brake systems can be purchased in the following configurations:

- TH-6000 Series – this system is designed to conform to all current FMVSS 571.121 regulations for air-over-hydraulic trailer brake systems. However, it is the trailer manufacturer’s responsibility to certify that their trailer meets these regulations.

- TH-5000 Series – this system does not meet all FMVSS regulations. Specifically, although ABS braking is provided, provisions are not made for the automatic application of mechanical parking brakes.

Features:

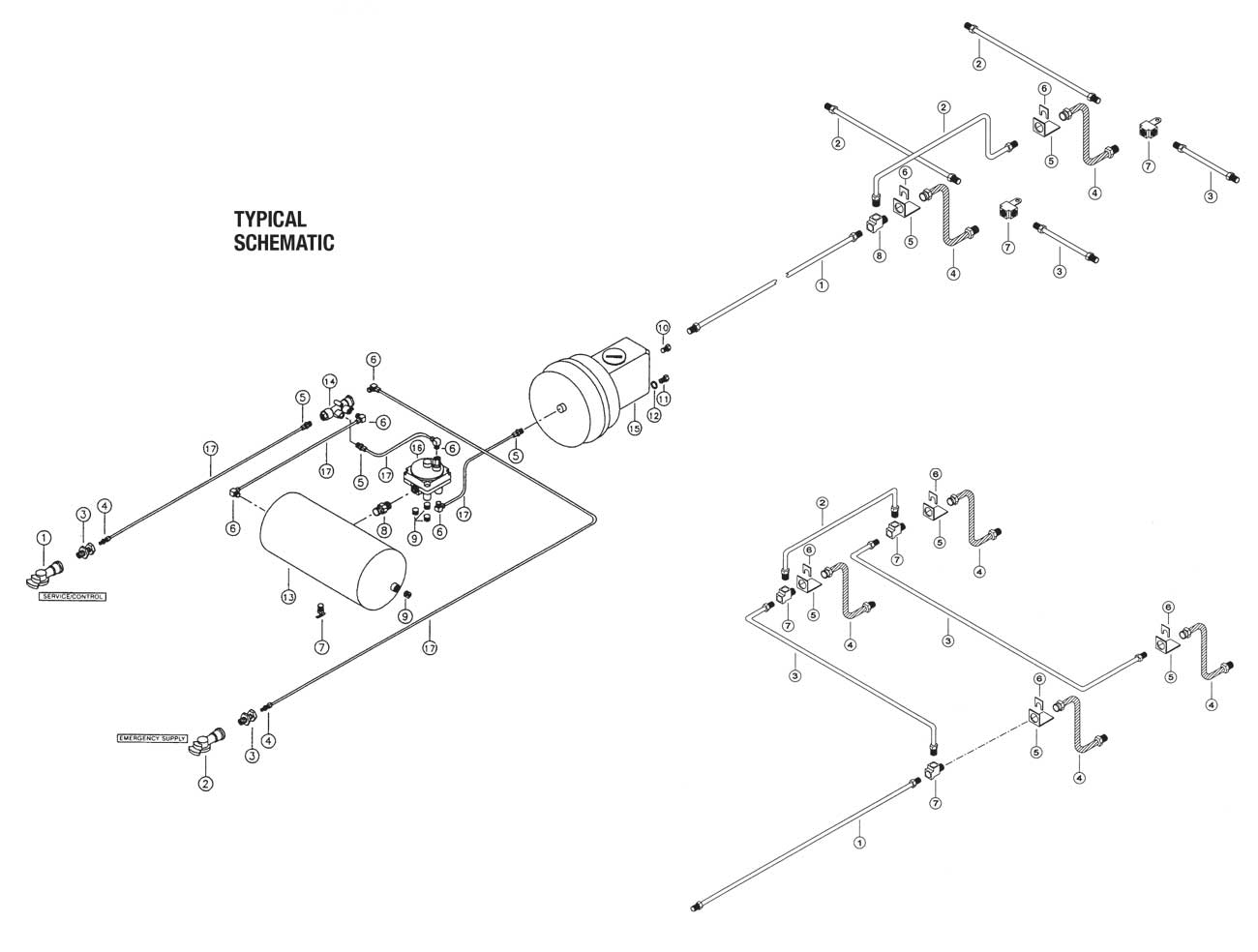

- Each kit furnished complete with control valves, air tank, air/hydraulic actuator, air hose and hydraulic brake line kit

- Custom kits are available. Contact us for more information.

The following table summarizes the most common TH-5000 and TH-6000 series Air/Hydraulic ABS kits.

TH-5000 & TH-6000 SERIES WITH ABS

The TH-6000 system requires all hydraulic brakes to be equipped with a mechanical parking brake. The axle manufacturer can supply their axles with a parking brake feature. The mechanical brakes are linked to a spring brake actuator via a series of cables and are controlled by the ABS relay valve. The hydraulic brakes are used for normal braking and the mechanical brakes are used for emergency braking and parking.

The TH-5000 system provides ABS braking via the hydraulic brakes. Emergency braking is provided via an emergency valve to the hydraulic brakes, but mechanical parking brake capabilities are not provided. It is possible to install mechanical brakes at a later date after the trailer is manufactured but not without considerable additional cost in materials and labor. Both systems are what is normally referred to as 2S/1M, meaning two sensor / one modulating valve. This is the minimum configuration required by FMVSS 571.121. A 2S/1M system will only sense wheel lockup on one axle on the trailer (the sensed axle). If wheel lockup is detected, all brakes are modulated via the ABS relay valve until normal braking is achieved. Because only one axle has ABS sensors, wheel lockup can occur on an unsensored axle and never be detected. The location of the sensed axle is determined based on the number of axles and the type of suspension used. While it is possible to design an air-over-hydraulic trailer brake system with sensors on more than one axle (a 4S/2M system), this would get quite expensive because each axle would require its own ABS valve, and air/hydraulic booster.

Ph: 574-277-2306 • Fax: 574-277-3785 • 2651 Hoyt Street Muskegon, MI 49444

Bludot Manufacturing © 2021